work in process inventory formula

The last quarters ending work in process inventory stands at 10000. 10000 300000 250000 60000 Work in process inventory 60000 The WIP figure indicates your company has 60000 worth of inventory thats neither raw material nor finished goodsthats your work in process inventory.

Pin By Mihir Ishwarlal On Table Metal Working Tools Feeding Tools Machine Tools

The total cost of Job 42A is 43200 Cost of goods manufactured 645 Then the formula is similar to our raw materials calculation Typically the more accurate the estimate the more detail is Enter the cost of materials labor manufacturing overhead beginning work in process inventory and ending work in process inventory into the calculator to determine the cost of.

. Although WIP inventory cannot yet be sold its considered an asset on a merchants balance sheet. Heres how youll need to do it. Build Your Online Store - Free Fast Easy.

Ad Get the Inventory Tools your competitors are already using - Start Now. To calculate the WIP precisely you would have to manually count each inventory item and determine the valuation accordingly. This excludes the value of raw materials not yet incorporated into an.

The calculation of ending work in process is. 02 180000 The first term of the right side Fq decreases systematically the higher the production level q 02 180000 19 per hour A recent trend in process research is to develop dynamic mathematical A recent trend in process research is to develop dynamic mathematical. WIP Inventory Example 1 Based on your previous accounting records your companys beginning WIP is 200000.

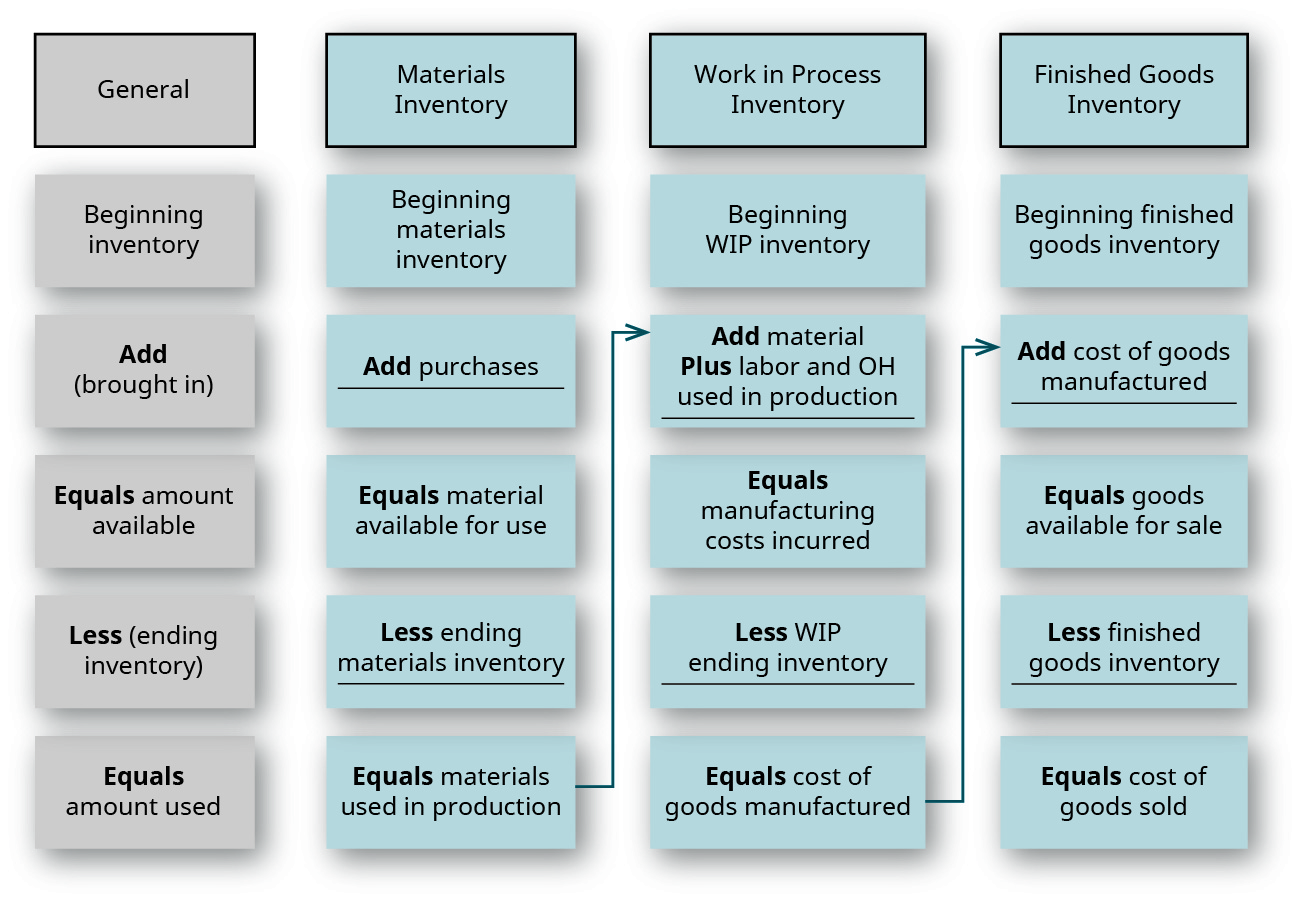

The work in process formula is expressed as. Beginning work in process amount manufacturing costs cost of manufactured goods For instance let us assume a company called Crown Industries who is into manufacturing furniture. How do you calculate work in process inventory.

To calculate the WIP precisely you would have to manually count each inventory item and determine the valuation accordingly. And each subsequent sub-process throughout the factory adds additional value. These items are typically located in the production area though they could also be held to one side in a buffer storage area.

The Role of Work in Process WIP Inventory in the Supply Chain. Try It Now Grow Your Business. Work-in-Process Inventory Formula Once you know your beginning WIP inventory manufacturing costs and COGM you can start to use the WIP inventory formula.

Once the manufacturer starts the production process those items are no longer raw materials. There are things it doesnt consider like waste spoilage downtime scrap and MRO inventory. The work in process formula is the beginning work in process amount plus manufacturing costs minus the cost of manufactured goods.

Create Your Own Online Store and Start Selling Today. Keep in mind this value is only an estimate. Ending WIP Inventory Beginning WIP Inventory Manufacturing Costs- Ending WIP Inventory Work In-process Inventory Example Assume Company A manufactures perfume.

How do you calculate work in process inventory. Therefore the direct labour and the operational cost of putting the kettle together would be classified under work in. WIP is calculated as a sum of WIP inventory total direct labor costs and allocated overhead costs.

Beginning WIP Inventory Manufacturing Costs COGM Ending WIP Inventory. The work in process inventory refers to the part of the production cycle of turning your individual raw materials into a kettle. 15000 225000 215000 25000.

Understanding the terms listed above is key to this process. To calculate the WIP inventory ie work in process inventory you need to use the following work in process inventory formula. In this example you would calculate your ending WIP inventory as follows.

Your WIP inventory formula would look like this. WIP or Work in Progress is a part of a companys overall inventory that has begun being processed but is not yet finished. In this case for example consider any manufactured goods as work in process.

As raw materials and components are consumed they gain value because they have incurred some labor and overhead. Total Cost Of Work In Process Formula. Beginning WIP Inventory Manufacturing Costs COGM Ending WIP Inventory.

Work in process work in progress goods in process or in-process inventory are a companys partially finished goods waiting for completion and eventual sale or the value of these items. To calculate beginning inventory subtract the amount of inventory purchased from your result. Ending WIP Inventory Beginning WIP Inventory Manufacturing Costs COGM Using this WIP formula businesses can calculate how much work in process inventory they will have left over at the end of the accounting period.

Standard Work is one of the more misunderstood concepts in Lean manufacturing. The WIP figure reflects only the value of those products in some intermediate production stage. For this reason its considered best practice to hold.

Add the value of goods added to work-in-process during the previous period to the beginning work-in-process inventory in the previous period. Choose Your Inventory Tools from the Premier Resource for Businesses. Beginning WIP Inventory Manufacturing Costs COGM Ending WIP Inventory Calculating WIP Inventory Examples Here are some simple examples to better understand WIP inventory.

To calculate your in-process inventory the following WIP inventory formula is followed. How do you calculate work in process inventory. Total Cost of Manufacturing Beginning Work in Process Inventory Ending Work in Process Inventory Cost of Manufactured Goods This formula can be manipulated algebraically to find values that your accounting is missing.

Work-in-process inventory is materials that have been partially completed through the production process. The total of all WIP inventory subsidiary ledgers matches the WIP inventory account shown on the balance sheet Solution Exhibit 17-35B summarizes the total Assembly Department costs for April 2009 calculates cost per equivalent unit of work done to date for direct materials and conversion costs and assigns these costs to units completed and. Fortunately you can use the work in process formula to determine an accurate estimate.

The ending WIP beginning WIP manufacturing costs - cost of goods produced This represents the value of the partially completed inventory which accounts for only a part of what the company will actually produce. Work in process inventory and work in progress inventory are interchangeable phrases for the most part. Adding the totals of these categories will give you your current work in process inventory.

For example if you do not know the Cost of Manufacturing you can use this altered version of the formula. Calculating Wip Inventory Examples. The formula for calculating the WIP inventory is.

Work in process inventory includes all raw goods production expenses and labor costs associated with producing merchandise inventory. Ad Try It Now. Fortunately you can use the work in process formula to determine an accurate estimate.

Beginning WIP Manufacturing costs - Cost of goods manufactured Ending work in process Example of the Ending Work in Process Calculation. The beginning WIP inventory cost refers to the previous accounting periods asset section of the balance sheet. Beginning WIP Inventory Manufacturing Costs Cost of Finished Goods Ending WIP Inventory If your head is spinning with all these figures dont worry.

The amount of ending work in process must be derived as part of the period-end closing process and is also useful for tracking the volume of production activity.

A Comprehensive Guide Taper Turning Methods 4 Types Of Taper Turning Operations In Lathe Machine Lathe Machine Turret Lathe Machining Process

Construction Management Hierarchy Construction Management Organizational Chart Design Management

Ending Work In Process Double Entry Bookkeeping

Download Sales Commission Calculator Excel Template Exceldatapro Excel Templates Excel Spreadsheet Template

Inventory Costing Bookkeeping Business Accounting Basics Inventory Accounting

All You Need To Know About Wip Inventory

A Manufacturer Can Ensure Quality While Scaling Up Production By Employing An Industry Specific Erp Software That Helps Them Consist Infographic Software Scale

Restaurant Inventory And Menu Costing Workbook Menu Restaurant Food Cost Food Truck Menu

Work In Process Wip Inventory Youtube

Reorder Point Calculating When To Reorder Tradegecko Safety Stock Point Formula

Reorder Point Calculator Excel Template Reorder Point Etsy Excel Templates Templates Excel

3 Types Of Inventory Raw Materials Wip And Finished Goods Youtube

Inventory Control Model Inventory Safety Stock Supply Chain Management

Wip Inventory Definition Examples Of Work In Progress Inventory

Explor 3 Different Types Of Machine Learning Algorithms With Use Cases Machine Learning Artificial Intelligence Machine Learning Machine Learning Deep Learning

Work In Process Inventory Formula Wip Inventory Definition

Financial Ratio Inventory Number Of Days While The Inventory Turnover Ratio Gives A Sense Of How Many Times The C Financial Ratio Inventory Turnover Financial

How To Implement Total Quality Management Tqm 6 Cs Of Tqm Manager Quotes Document Management System Staff Motivation

Use The Job Order Costing Method To Trace The Flow Of Product Costs Through The Inventory Accounts Principles Of Accounting Volume 2 Managerial Accounting